How Brass Inserts Improve the Performance of Electrical and Electronic Devices

In the world of electrical and electronic devices, precision, durability, and reliability are essential. One of the most overlooked yet crucial components contributing to these qualities is brass inserts. These small but powerful components play a significant role in improving the performance, longevity, and efficiency of various electrical and electronic applications.

Understanding Brass Inserts

Brass inserts are threaded metal components used to create strong and durable fastening points in plastic or soft materials. They are commonly installed through press-fitting, heat installation, or ultrasonic insertion. Due to their excellent machinability, corrosion resistance, and electrical conductivity, brass inserts are preferred over other materials like steel or plastic.

Benefits of Brass Inserts in Electrical and Electronic Devices

- Enhanced Electrical Conductivity

Brass is an excellent conductor of electricity, making brass inserts ideal for electrical applications. Unlike plastic or other materials, brass ensures efficient current flow, reducing energy loss and enhancing the performance of electrical devices.

- Corrosion Resistance

Electrical and electronic devices are often exposed to varying environmental conditions, including moisture and temperature fluctuations. Brass has a natural resistance to corrosion and oxidation, which prevents degradation over time, ensuring long-lasting performance.

- Strong and Reliable Fastening

Brass inserts provide strong and durable threads in soft materials such as plastic. This enhances the structural integrity of electrical components, preventing loosening or failure due to vibrations or repeated use.

- Thermal Stability

Electronic devices generate heat during operation. Brass inserts possess excellent thermal conductivity and stability, reducing the risk of expansion or contraction-related failures in high-temperature environments.

- Versatility in Applications

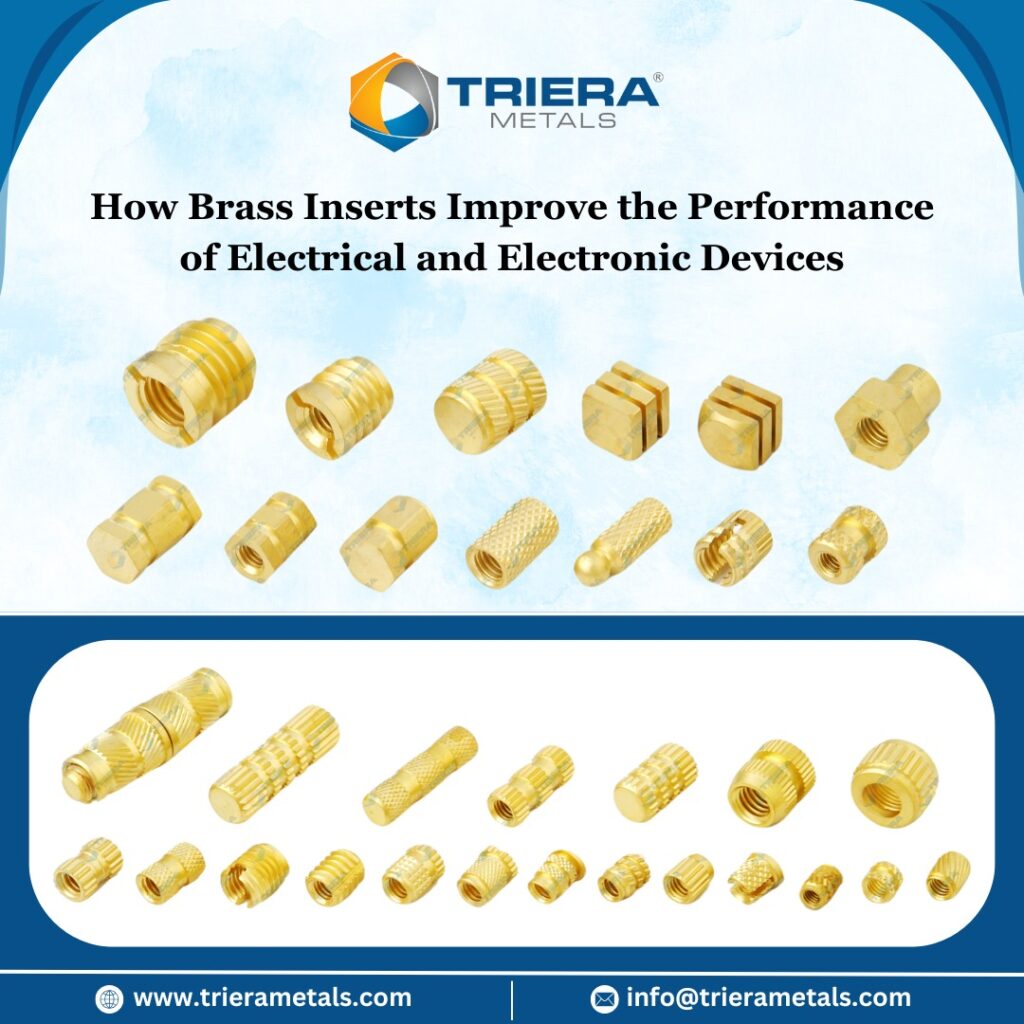

Brass inserts come in various sizes and types, such as threaded, hexagonal, knurled, and ultrasonic inserts. This versatility makes them suitable for a wide range of electrical and electronic devices, including circuit boards, connectors, power distribution systems, and enclosures.

- Easy and Secure Installation

The installation of brass inserts is straightforward and efficient, whether through heat staking, ultrasonic welding, or press-fitting. Once installed, they offer a permanent and robust fastening solution that reduces maintenance costs and enhances reliability.

- Resistance to Wear and Tear

Electrical components are subject to frequent assembly and disassembly for repairs, upgrades, or maintenance. Brass inserts provide wear-resistant threads that extend the lifespan of the devices by preventing thread stripping or deformation.

Applications of Brass Inserts in Electrical and Electronic Devices

- Printed Circuit Boards (PCBs): Brass inserts provide reliable mounting solutions for circuit boards, ensuring secure fastening and better conductivity.

- Connectors and Terminals: Used in power and signal connectors, brass inserts improve electrical conductivity and structural strength.

- Switchgear and Control Panels: The durability and corrosion resistance of brass inserts enhance the longevity and performance of control panels.

- Consumer Electronics: From smartphones to household appliances, brass inserts are widely used to ensure strong and reliable connections.

- Automotive Electronics: The thermal and mechanical stability of brass inserts make them essential in automotive electronic systems.

Conclusion

Brass inserts are indispensable components in electrical and electronic devices. Their superior conductivity, corrosion resistance, and durability make them the preferred choice for manufacturers aiming to improve product performance and longevity. Whether in consumer electronics, automotive systems, or industrial applications, brass inserts provide a reliable, cost-effective, and efficient solution for fastening and connectivity needs.

By integrating high-quality brass inserts into your designs, you can ensure enhanced functionality, longer service life, and improved overall performance of electrical and electronic devices.