Our Capabilities

Casting

- Why Casting?

- Types of Casting

- Shapes and profiles which cannot be either machined or forged, particularly with inner cores

- Grain Structure compactness is not critical

- Save Machining operations

- Centrifugal Casting

- Investment Casting

- Sand Casting

- Pressure Die Casting

Forging

- Why Forging?

- Types of Forging

- More economical for higher production run due to lesser material requirements

- Reduced Machining Operations

- Those profile which cannot be machined

- Open Die Forging

- Close Die Forging

- A) Solid Forging

- B) Hollow Forging

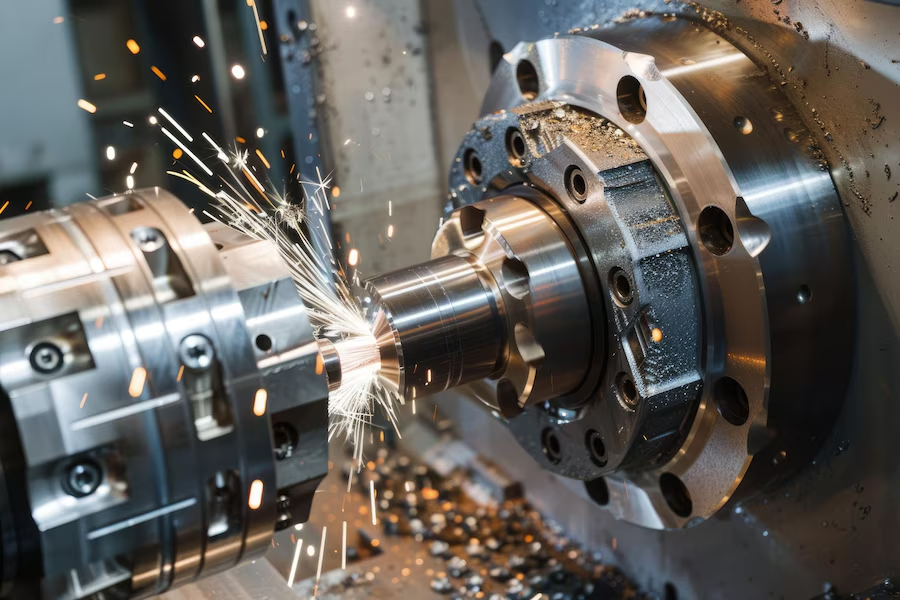

Machining

- Machining

- Types of Machining carried out

- Machining Capacity

Machining is done so as to make a piece of raw material cut into a desired final shape and size by a controlled material- removal process. Much of modern-day machining is carried out by Computer Numerical Control (CNC) machine, in which computers are used to control the movement and operation of the mills, lathes and other cutting machines.

- Turning

- Drilling

- Boring

- Reaming

- Milling

- Threading

- Broaching

- * 3mm to 300 mm

- * 0.010 mm as lowest tolerances for turning

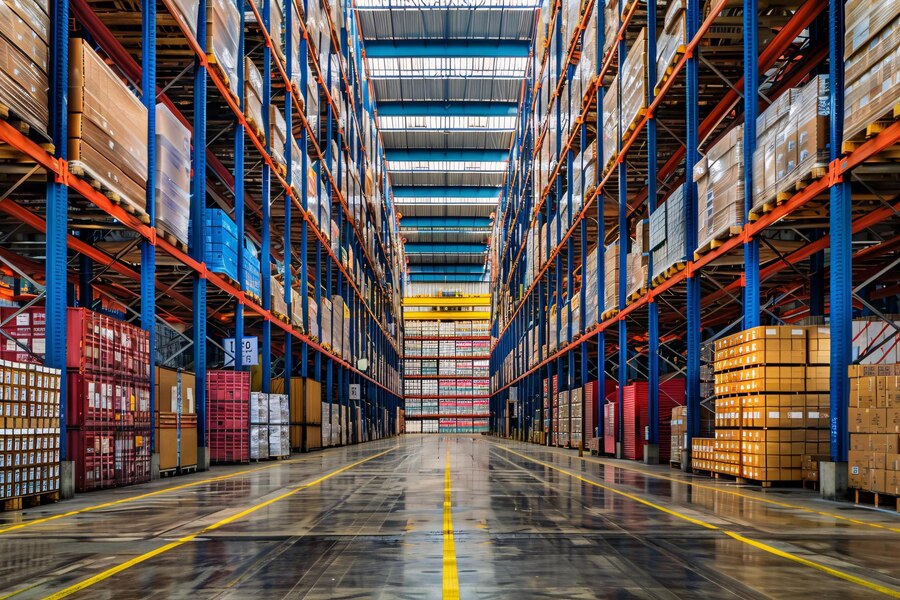

Warehousing

- Warehousing

- We offer warehousing facility for scheduled orders to facilitate faster deliveries. This is mainly provided to our Foreign Customers, however we can offer it domestically as well.

- Please contact us for more information about location and charges and duration for storage.

Surface Treatments

- We have approved vendors to handle all the plating requirements i.e. Silver Plating, Gold Plating, Copper Plating, Nickle Plating, Tin Plating, Chrome Plating, Brass Plating etc.

- Types of Surface Treatment offered.

- Nickel Plating

- Chrome Plating

- Silver / Gold Plating

- Brass Plating

- Nickel is done after copper plating on Brass for better bonding. We offer Nickel plating up to 50 microns with test reports.

- Chrome Plating is done after Nickle and Copper as base plating. This is mainly done for aesthetic purpose in Sanitary and Plumbing Parts.

- Silver / Gold Plating is done after copper plating on brass for better bonding. We offer plating as per customer specification with test reports.

- Brass Plating is done on Steel as well as Brass.

- Tin Plating

- Grinding / Buffing

- Annealing

- Stress Relieving

- Tin Plating is done after copper plating. For better results, it is advisable to do Nickel Plating on Copper and then do the Tin Plating.

- We do Grinding-Buffing to remove the lines, dents, scratches etc. and to create a bright surface finish. This is normally done for aesthetic purpose.

- Annealing is a process that heats the Brass to make it softer and more ductile, effectively reversing the work hardening process. We offer this service based on customer requirement.

- Stress relieving is normally done to relieve stresses developed during processes. We offer this service based on customer requirement.