Role of Advanced Technology in Manufacturing High-Grade Brass Electronic Parts

Why choice of material matters for brass electronic parts

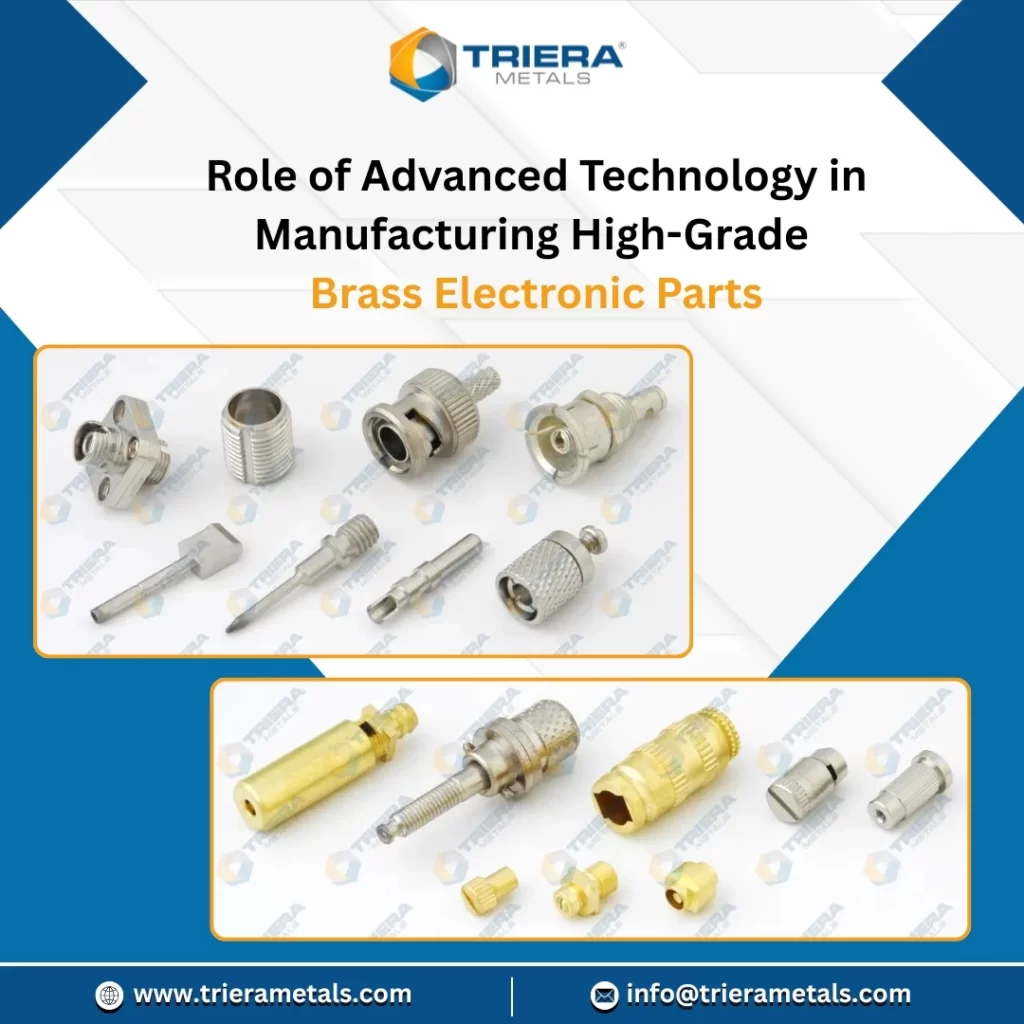

Brass is a well-established material for electronic components because it combines excellent electrical conductivity with high mechanical strength and corrosion resistance. When producing brass electronic parts (such as sockets, connectors, pins and spacer components), the alloy grade, surface finish, dimensional accuracy and plating all become critical. At Triera Metals, we work with high-quality brass alloys and deploy finishing processes aligned to customer needs (natural brass, nickel-plated, tin-plated, etc.).

However, the material alone doesn’t guarantee performance—how that material is processed, controlled and verified matters just as much. That’s where advanced technology becomes a game-changer.

Advanced machining and manufacturing techniques

Modern manufacturing of brass electronic parts employs CNC turning, milling, multi‐axis machining and automated lathes. These processes ensure tighter tolerances, consistent part geometry, reduced scrap and faster cycle times. Triera Metals emphasises these technologies to deliver precision components that meet exacting specifications.

Moreover, automated tooling and software-controlled systems reduce human error, improve repeatability and make complex geometries feasible—such as miniaturised connectors, high-pin-density sockets or intricate brass inserts for electronics assemblies.

Quality assurance through digital inspection and process control

For high-grade brass electronic parts, quality assurance cannot rely solely on visual inspection. Advanced technologies like coordinate measuring machines (CMM), optical scanning, in-line laser measurement and automated statistical process control (SPC) are increasingly deployed. These technologies monitor each batch of components for dimensional accuracy, finish quality, plating uniformity and material integrity.

Triera Metals highlights a commitment to “world-class quality” and the use of modern facilities and appropriate technology to enhance production and communication.

With these tools, customers receive components that conform reliably to standards—such as DIN, ISO, ASTM or customer-specific requirements.

Customization, agility and prototyping

Surface finishing, plating and material optimisation

Beyond basic brass machining, the performance of electronic components depends on post-processing: plating (nickel, tin, gold, etc.), passivation, knob finishing and cleaning. Advanced plating equipment, precise bath chemistry controls, and automated rinsing/drying lines ensure that each brass electronic part exhibits excellent corrosion resistance, ensures high conductivity at interfaces and meets surface-finish specifications.

Triera Metals emphasises that their components are offered in various grades, finishes and standards to meet diverse client needs.

Employing these finishing technologies safeguards performance in applications such as electronics connectors, PCB assemblies, switchgear and telecommunication equipment.

Integration of Industry 4.0, traceability and data analytics

Modern manufacturing doesn’t stop at physical machines. The rise of Industry 4.0 brings sensors, real-time monitoring, machine-learning optimisation and complete traceability of parts. For brass electronic parts, this means from raw-material batch to finished component, all process data (temperature, cycle time, tooling wear, plating thickness) can be recorded, analysed and used to drive continuous improvement.

Triera Metals’ facility emphasises “appropriate use of technology to enhance services and communication” and has an in-house R&D and innovation unit.

Such a framework supports traceability, faster root-cause analysis and ensures that the finished parts not only meet spec but also perform reliably in the field.

Applications and benefits of advanced-tech manufactured brass electronic parts

When brass electronic parts are manufactured using advanced methods, the downstream benefits are significant:

- Superior dimensional accuracy and fit in assemblies — reducing rework or rejection.

- Enhanced electrical performance owing to better material integrity and finishes.

- Longer service life and reliability in harsh or corrosive environments.

- Greater readiness for automated assembly in electronics manufacturing (pick-and-place, wave‐soldering, robotic insertions).

- Customisation without excessive cost — supporting niche and high-volume markets alike.

Because of these advantages, components from Triera Metals serve industries such as telecommunications, automation, electronics manufacturing, and switching systems.

Conclusion

The manufacturing of high-grade brass electronic parts is moving swiftly towards ever greater integration of advanced technologies—automated machining, in-line inspection, smart data analytics, flexible production and surface-engineering. For a company like Triera Metals, the embrace of these technologies ensures not just that they supply brass components, but that they supply premium, reliable, traceable electronic parts that match the evolving demands of customers and the electronics industry at large.

In an era where electronics continue to shrink, performance demands rise and reliability cannot be compromised, investing in advanced manufacturing isn’t a cost centre—it’s a competitive advantage. Triera Metals exemplifies how leveraging high-precision brass machining, state-of-the-art inspection, and smart manufacturing practices enable the production of world-class brass electronic parts that stand up to the tests of time, market changes and performance expectations.