Understanding the Manufacturing Process of Brass Automotive Components

Why Brass is Preferred in the Automotive Industry

Types of Brass Used in Automotive Manufacturing

Depending on the application, different brass alloys are used:

- Free-Cutting Brass: Best suited for high-speed machining and intricate designs.

- High Tensile Brass: Offers superior strength and is used in components that endure mechanical stress.

- Naval Brass: Resistant to corrosion and wear, making it suitable for parts exposed to moisture or chemicals.

Each alloy is chosen based on the specific requirements of the automotive system in which it will function.

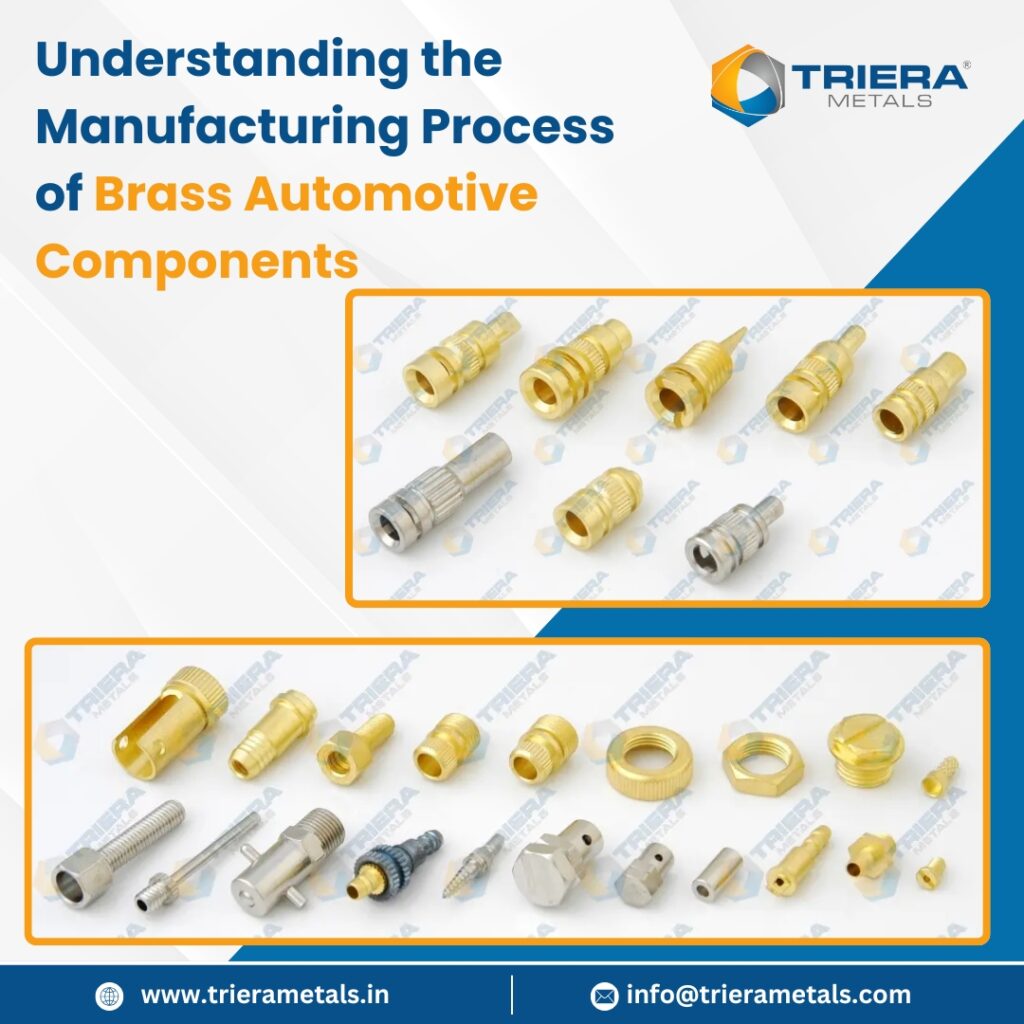

Applications of Brass Automotive Components

Brass components are integral to various vehicle systems, including:

- Fuel Systems: Valves, adapters, and fittings that require tight sealing and corrosion resistance.

- Electrical Systems: Connectors, terminals, and switches that benefit from brass’s conductivity.

- Braking Systems: Hydraulic connectors and pressure fittings.

- Cooling Systems: Radiator components and water connectors.

These applications demonstrate the versatility and reliability of brass across multiple automotive functions.

Step-by-Step Manufacturing Processy

1. Raw Material Selection

2. Melting and Alloying

3. Casting Process

The molten alloy is poured into molds to form billets or rods.

- Sand Casting is used for larger, complex parts.

- Die Casting is ideal for producing high-volume, precise components.

This stage shapes the foundation for further forming and machining processes.

4. Forging and Forming

5. Machining Operations

6. Surface Finishing

7. Quality Inspection and Testing

Before dispatch, every brass component undergoes detailed quality inspection.

- Dimensional checks ensure accurate sizes and tolerances.

- Mechanical testing verifies strength and hardness.

- Corrosion and leakage tests confirm long-term reliability under operating conditions.

This thorough testing guarantees that only defect-free components reach the end customer.

Sustainability in Brass Manufacturing

Challenges in Brass Component Production

While brass is highly versatile, its production process comes with challenges.

Maintaining a consistent alloy composition is critical to prevent variations in mechanical properties. Machining brass also generates fine chips that require proper recycling management. Manufacturers continue to adopt innovative machining techniques and waste control systems to enhance productivity while maintaining sustainability.