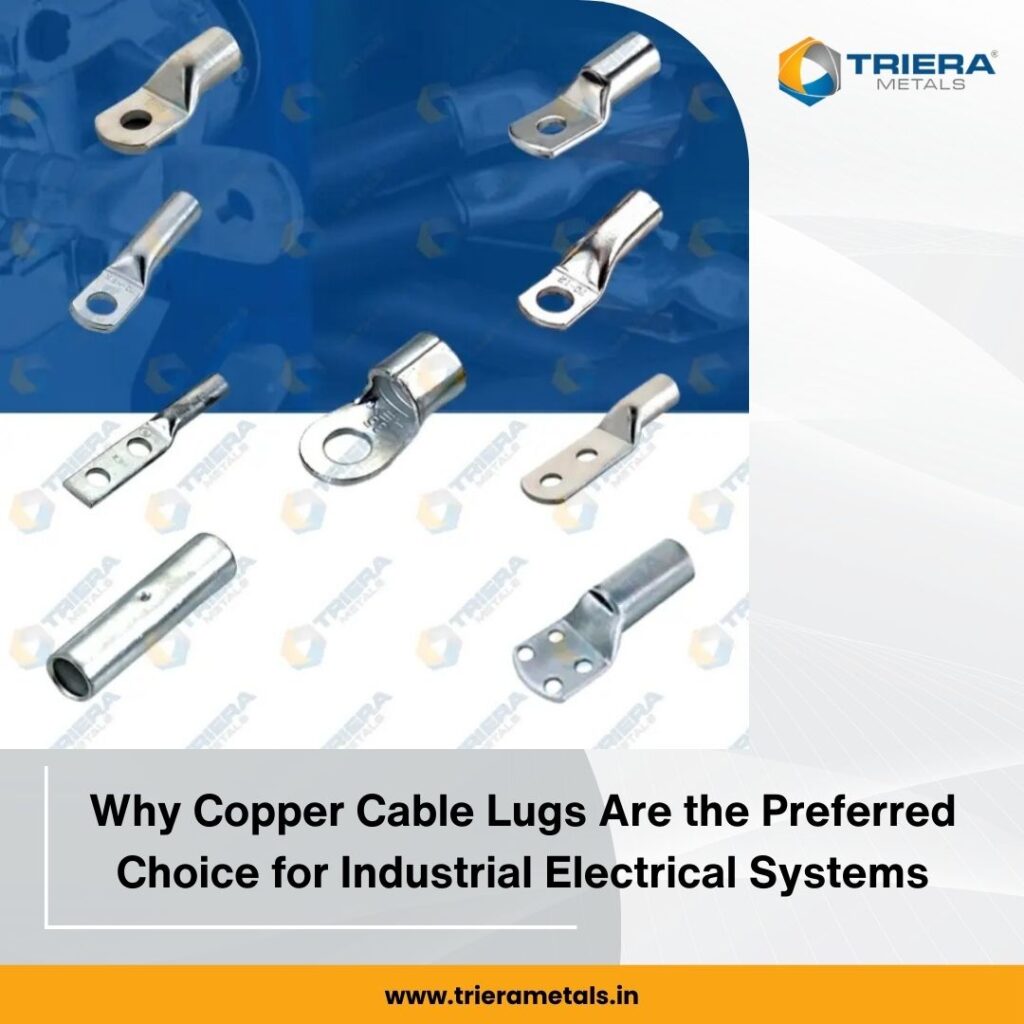

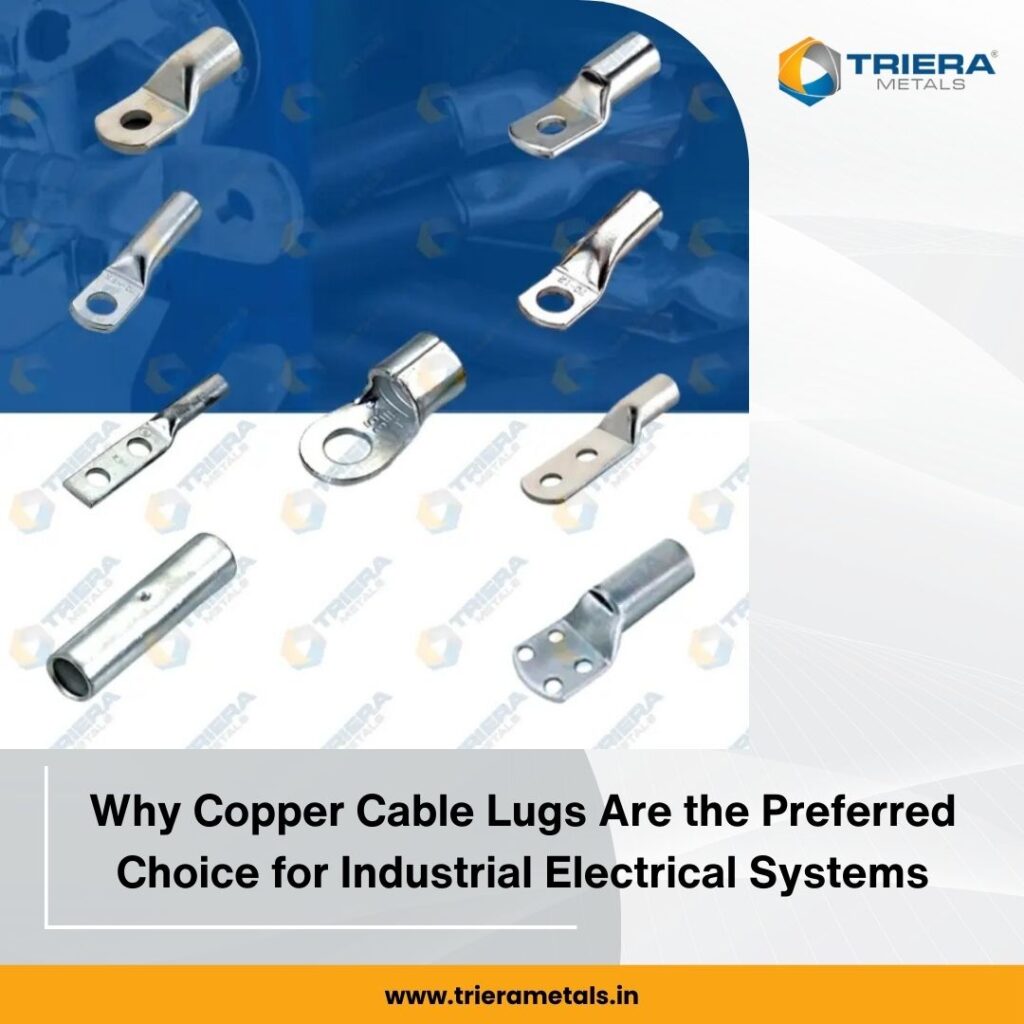

Why Copper Cable Lugs Are the Preferred Choice for Industrial Electrical Systems

In the world of industrial power distribution, every component—no matter how small—plays a critical role in maintaining system integrity and operational safety. One such component is the cable lug, a simple yet vital electrical connector that ensures secure and efficient power transfer between conductors and terminals.

While there are several types of cable lugs made from different materials, copper cable lugs remain the preferred choice for most industrial applications. At Triera Metals, we specialize in manufacturing high-quality copper lugs designed to deliver superior electrical performance, mechanical reliability, and long-term durability.

In this blog, we explore what makes copper lugs the go-to solution for industrial electrical systems and how Triera Metals brings unmatched value to this essential product.

What Makes Copper Cable Lugs Stand Out?

It boasts an array of physical and chemical properties that make it ideal for high-performance connectors like cable lugs.

- Exceptional Electrical Conductivity

Copper offers excellent conductivity, second only to silver. This means less resistance in the connection, leading to minimal energy loss and reduced heat generation. In high-load systems, this translates to better efficiency and safer operation.

- Superior Corrosion Resistance

Industrial environments can be harsh—exposed to moisture, chemicals, and fluctuating temperatures. Copper’s natural resistance to corrosion makes it a dependable material for long-term performance, especially when combined with protective coatings like tin plating, which we offer at Triera Metals.

- Mechanical Strength and Malleability

They are easy to crimp or solder, making installation faster and more secure without compromising the integrity of the cable. This is particularly important in tight installation spaces or when working with delicate electrical equipment.

- Thermal Stability

Copper spreads heat quickly, which helps keep electrical connections cool and safe during use. This helps maintain the stability of the connection even under heavy electrical loads, reducing the risk of overheating and fire hazards.

Applications of Copper Cable Lugs

- Power Generation and Distribution

- Control Panels and Switchboards

- Renewable Energy Systems (Solar, Wind)

- Automotive and EV Infrastructure

- Heavy Machinery and Equipment

- Marine and Railways

Their reliability and performance under demanding conditions make them indispensable in systems where safety and uptime are non-negotiable.

Why Choose Triera Metals for Copper Cable Lugs?

At Triera Metals, we believe quality starts at the source. That’s why we use 99.9% pure electrolytic copper for our cable lugs, ensuring excellent conductivity and longevity. But we don’t stop there. Here’s what sets us apart:

- Precision Manufacturing

Every lug fits perfectly, minimizing installation effort and maximizing performance. - Custom Options Available

Have a specific requirement? We provide custom-designed cable lugs tailored to your application—whether it’s a unique hole size, shape, or crimping standard. - Compliant with International Standards

Our lugs are tested to meet or exceed global standards such as IS, DIN, and BS, giving you confidence in their performance and safety. - End-to-End Customer Support

From product selection to post-sale support, our experienced team is here to guide you through every stage, ensuring a smooth and successful integration into your systems.

Conclusion

Their unmatched conductivity, durability, and thermal stability make them the connector of choice in a wide array of industrial settings.

At Triera Metals, we combine top-grade materials with engineering excellence to deliver cable lugs that power your operations with confidence. Whether you’re developing a new project or upgrading an existing system, we have the solutions you need—on time and to specification.