quality

We at Triera Metals ensure by providing utmost possible

product & service to customers

We are committed to continuously refining our processes to deliver superior quality products to our valued customers. Our dedication to quality is rooted in a strong belief in both Quality Assurance and Quality Control. To ensure consistent excellence, we rigorously follow the PDCA Cycle, which stands for Plan, Do, Check, and Act. This systematic approach allows us to meticulously plan our processes, execute them effectively, monitor outcomes, and implement necessary improvements. By adhering to the PDCA Cycle, we not only maintain high standards but also foster a culture of continuous improvement, ensuring that our products consistently meet or exceed customer expectations.

Step 1 - Plan

"Plan" is planning and establishing the process related objectives and determine the processes that are required to deliver a high-Quality end product.

Step 2 - Do

"Do" here represents actually developing and testing processes in order to achieve our planned objectives.

Step 3 - Check

"Check" here refers Monitoring of processes, modify the processes, and check whether it meets the predetermined objectives.

Step 4 - Act

"Act" is implementing actions that are necessary to achieve improvements in the processes.

Quality Policy

-

Quality Assurance

-

Our Aim

-

Quality Control

Triera Metals utilizes Quality Assurance to meticulously design and implement products following the correct procedures from the outset. This proactive approach helps us identify potential issues early in the production process, minimizing the likelihood of defects and errors in the final product. By adhering to strict quality standards and protocols, we ensure that every stage of production is thoroughly monitored and controlled. This commitment to Quality Assurance not only enhances the reliability and performance of our products but also builds customer trust by consistently delivering products that meet or exceed expectations. Our focus on preventive measures and continuous process improvement is key to maintaining the high level of quality that our customers have come to expect from Triera Metals.

Our goal with Quality Control is to rigorously verify that our products meet the exact specifications and requirements set by our customers. This process involves not only inspecting and testing the products but also evaluating our team’s skill sets to ensure they are equipped with the necessary expertise to maintain high-quality standards. We invest in continuous training and certifications for our workforce, empowering them to deliver exceptional results. At Triera Metals, we are committed to providing “perfect” service to our valued customers around the world, ensuring that every product we deliver is of the highest quality and fully aligned with our clients’ needs. Our unwavering focus on Quality Control is a key factor in our ability to consistently exceed customer expectations and maintain our reputation for excellence in the global market.

We have established well-defined initial tolerance limits for clinical trial data and procedural metrics during risk identification, enabling us to detect deviations from the acceptable range early in the process. This proactive approach allows us to address potential issues before they impact the final product. At Triera Metals, we recognize the critical importance of maintaining Tight Tolerance to ensure top quality and superior performance in every product we deliver. Our commitment to tight tolerance begins at the product design stage and continues through material selection, manufacturing, tooling, and testing, all the way to final delivery. By adhering to these stringent standards, we ensure that each product not only meets but exceeds the highest industry benchmarks. This attention to detail guarantees that our customers receive the finest products, designed and manufactured with precision, reliability, and excellence.

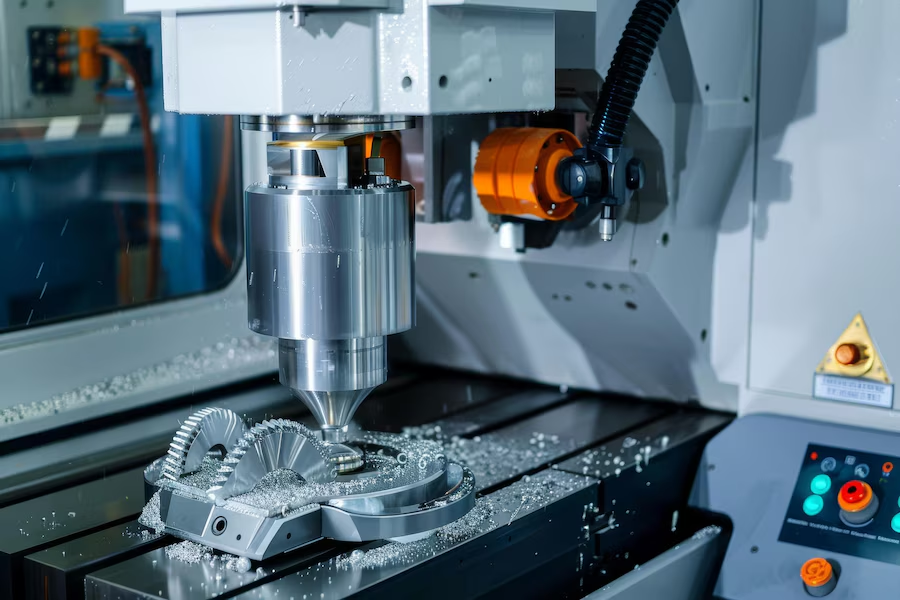

Our Manufacturing Process

General Manufacturing Process In Brief

Raw

Material

Inspection of Raw

Material

Cutting and Resize as per Required

Machining

Inspection and Online Quality Check

Finishing

Final

Inspection

Assembly

Packaging